Bridging Data Silos in Mining with AI-Driven Solutions

Mining operations generate vast amounts of data, but fragmented and siloed information prevents companies from fully leveraging it. As highlighted in Boon Solutions’ feature in the Australian Mining Review (February edition), mining businesses often struggle with disconnected systems, making it difficult to gain a real-time, complete view of their operations.

Contents

Breaking Down Mining Data Silos to Reduce the Performance Gap

Without seamless data integration, mining companies can face:

Limited visibility across operations – Disconnected data sources make it difficult to track production, equipment health, workforce safety, and environmental compliance in real time.

Slow, reactive decision-making – Key insights are often buried in spreadsheets or locked within separate departments, causing delays in responding to operational challenges.

Increased operational risks – Poor integration between financial, maintenance, and production data leads to inefficiencies, higher costs, and unnecessary downtime.

These challenges contribute to the performance gap between a mine’s full potential and its actual efficiency. The key to bridging this gap is breaking down data silos and creating a unified source of operational intelligence.

How Data Silos Impact Mining Business Outcomes

Mining companies typically manage data across multiple systems—including ERP platforms such as SAP and Pronto, SCADA systems, IoT sensors, and legacy databases. However, these systems often operate in isolation, leading to:

1. Production Inefficiencies

Without real-time data synchronisation between production planning tools and operational data, site managers lack accurate insights into ore recovery rates, processing efficiency, and equipment utilisation. As a result, production schedules are often based on historical trends rather than live data, leading to inefficiencies and delays.

2. Equipment Downtime & Maintenance Delays

Predictive maintenance is nearly impossible when data from asset monitoring systems, Pronto maintenance modules, and work order logs is not centralised. Can lead to unplanned equipment failures, higher repair costs, and lost production time.

3. Safety & Compliance Risks

Mine safety depends on real-time monitoring of environmental data, geotechnical readings, and workforce activity. If safety-related data is stored in separate systems, companies can face compliance risks and slower responses to hazardous incidents.

4. Slow Reporting & Decision-Making

Senior business leaders rely on timely, accurate data for investment planning and resource allocation. When data silos exist, report generation is slow, delaying critical business decisions.

Solving Mining Data Silo Issues for Real-World Impact

Better reporting tools can help—but optimal is a structured approach to data integration and analysis. AI-powered analytics, machine learning, and cloud platforms can provide mining companies with a unified, real-time data strategy that delivers tangible business outcomes.

1. Creating a Unified Data Layer for Real-Time Decision-Making

– Centralising disparate data sources into a single analytics platform ensures that production, maintenance, and compliance teams all work from the same real-time data.

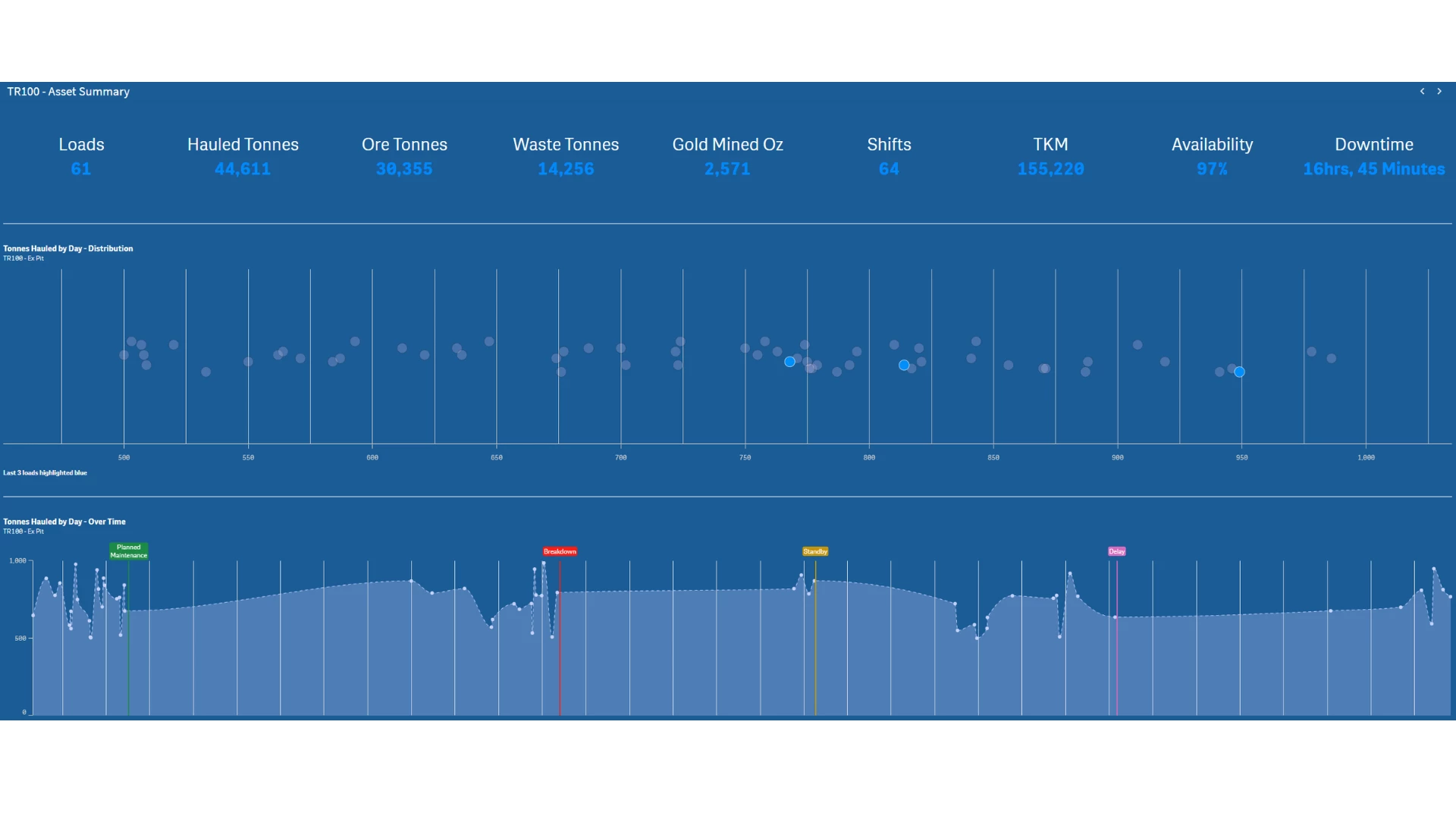

– AI-powered dashboards provide instant visibility into mining KPIs, including haul cycle times, ore quality variations, and equipment efficiency.

Impact: Faster, data-driven decision-making and proactive responses to production inefficiencies.

2. Enabling Predictive Maintenance to Reduce Equipment Downtime

– AI-driven analytics process IoT sensor data from mining equipment to predict failure patterns before breakdowns occur.

– Automated maintenance scheduling ensures that work orders in Pronto or SAP are prioritised based on real-time asset condition rather than pre-set maintenance cycles.

Impact: Lower unplanned downtime, reduced maintenance costs, and extended asset lifespan.

3. Enhancing Safety & Environmental Compliance

– Automated risk detection analyses geotechnical reports, environmental monitoring data, and compliance logs to flag potential hazards.

– AI-powered incident tracking ensures real-time safety monitoring and faster responses to regulatory compliance requirements.

Impact: Improved safety culture, better regulatory compliance, and lower environmental risks.

4. Accelerating Data-Driven Decision-Making for Business Leaders

– Automated data pipelines eliminate the need for manual report consolidation, ensuring business leaders always have up-to-date insights.

– AI-powered simulations enable executives to model different operational scenarios, optimising resource allocation and reducing costs.

Impact: Faster, more informed business decisions that enhance operational efficiency and profitability.

Bridging the Performance Gap with AI-Driven Data Integration

As highlighted in Boon Solutions’ feature in the Australian Mining Review (February edition), data silos remain one of the biggest challenges holding mining companies back from reaching their full potential. Companies that continue operating with fragmented, outdated data structures will struggle to compete, while those that embrace AI-driven analytics and real-time integration will gain a competitive advantage.

To bridge the performance gap, mining leaders need to:

✅ Evaluate their current data landscape – Identify where data silos exist and how they impact operations.

✅ Implement AI-driven data integration – Unify ERP systems like SAP and Pronto with real-time operational data.

✅ Empower teams with real-time analytics – Ensure decision-makers at all levels have instant access to critical insights.

By taking these steps, mining companies can reduce operational risks, optimise productivity, and future-proof their operations.

‘The first step is data integration and consolidation where we collate data from multiple sources into a unified platform to essentially create a single source of truth. We then look at data quality management as poor data quality can derail AI projects before they begin. Ensuring data accuracy, completeness and consistency is the next foundational step…’

Boon Keat Law, Boon Solutions

📖 Read More: Boon Solutions’ feature in the Australian Mining Review (February edition) explores how AI-driven analytics can eliminate mining data silos for better business outcomes.

Ready to put AI in action to elevate your data strategy?

Connect with us to explore how AI can empower your organisation.